BOW MAKING

Here are some random images that highlight the many steps and elements that go into crafting a glass laminated longbow. See the datasheets for more details or contact me with any questions regarding my bow building process.

Datasheets

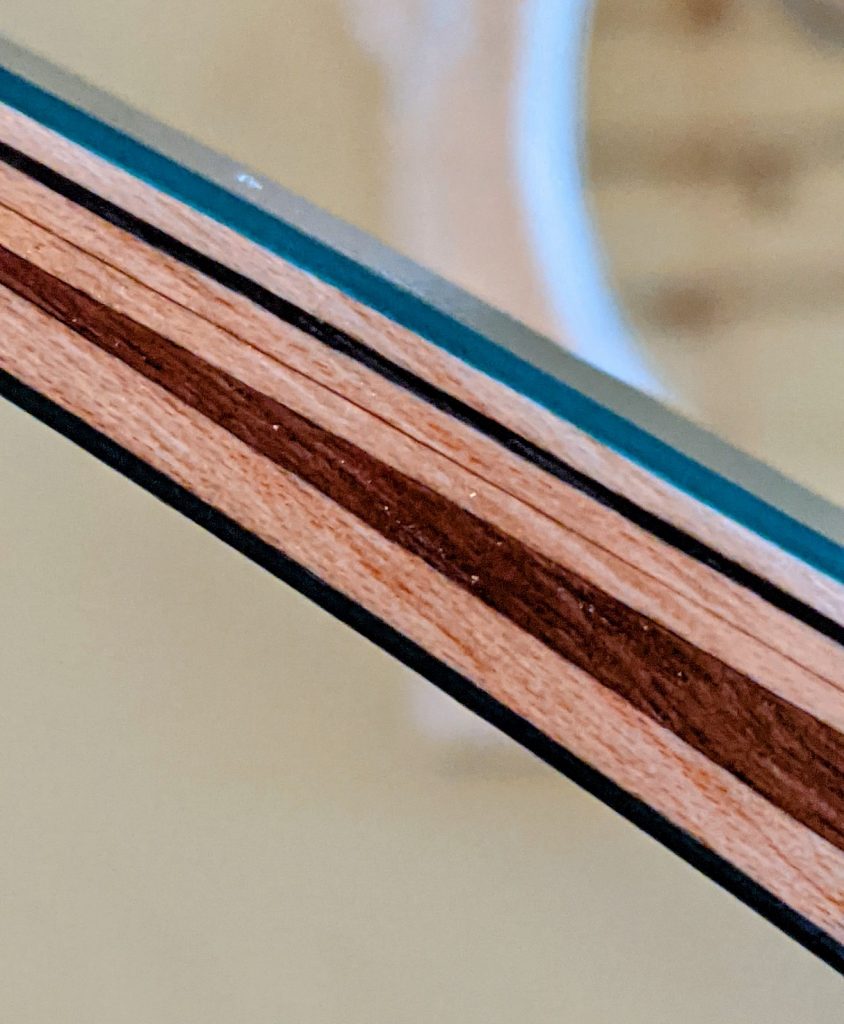

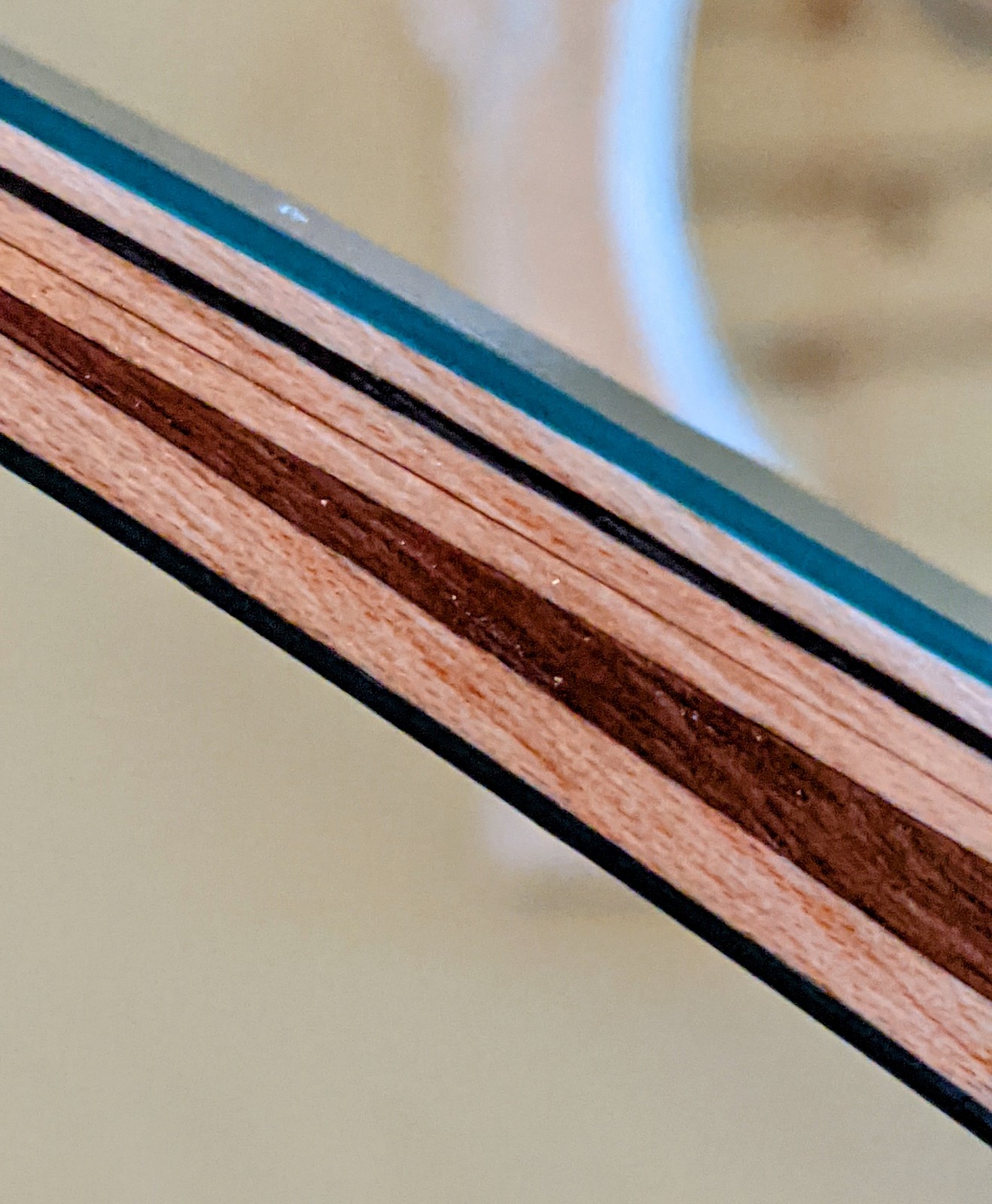

This one-piece longbow is designed has tapered reflex/deflex limbs for a smooth feel and high responsiveness. The bocote wood riser is enhanced with hard maple and red G10 fiberglass insert strips and overlays. The riser components are laminated with G-Flex 650 epoxy cured for 3 hours at 140 degrees. The limbs consist of 1 tapered and 3 parallel strips of hard maple sandwiched between back and belly layers of black fiberglass. A .020″ layer of carbon fiber is laminated in the core for increased strength, stiffness and performance. The bow was glued-up with Huntsman TDR-1100 high strength epoxy, oven cured at 165 degrees for 6 hours and shaped by hand, resulting in a tough but smooth shooting bow. The limb tip overlays are dyed and resin- stabilized tamarind wood to handle high-performance bowstrings (a BCY 8125G continuous loop string is included). String silencers are merino wool yarn, hand-spun and dyed by Gale’s Art). The limb edges were rubbed with 4 coats of shellac and the bocote riser was sealed with CA “superglue” to counter the natural oiliness of this wood. The bow was top coated with 3 coats of Thunderbird Epoxy and hand rubbed with 0000 steel wool and bowling alley wax for a very tough finish.

| AMO Length | 64″ |

| Draw Weight | 45# @ 28″ |

| Brace Height | 7 1/2 |

| Tiller | Even |

| Nock Height | 5/8″ |

Test Arrows:

PSE Carbon Force Timber 500 Spine • 30” • 150gr Point • Total Weight 389gr

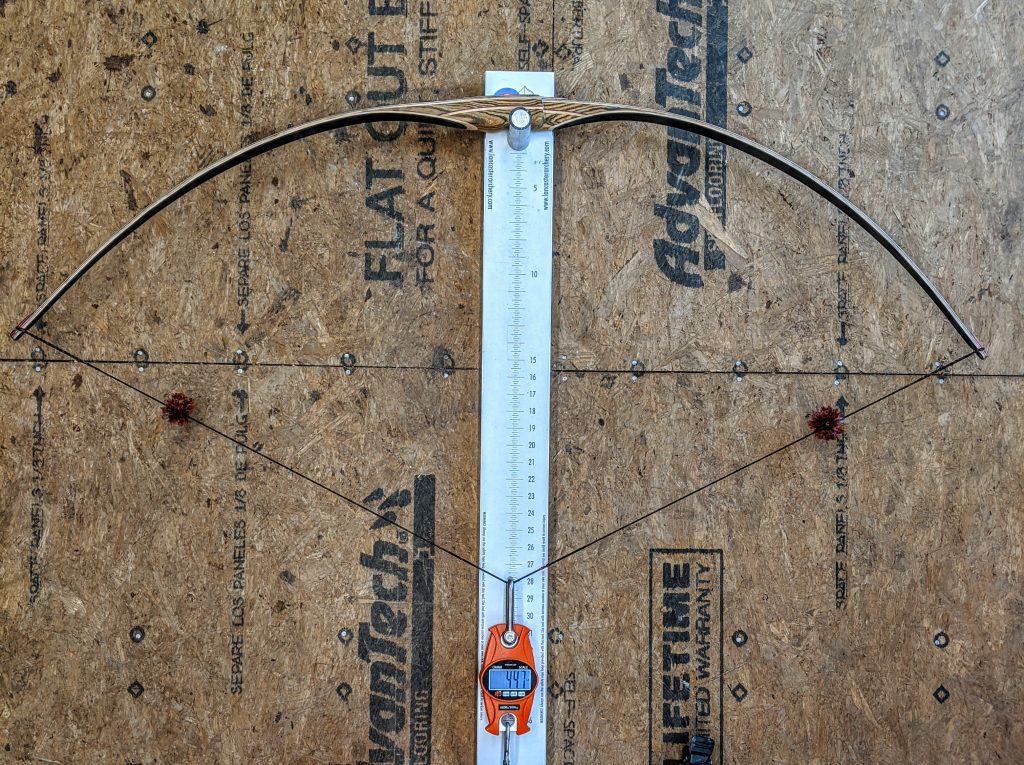

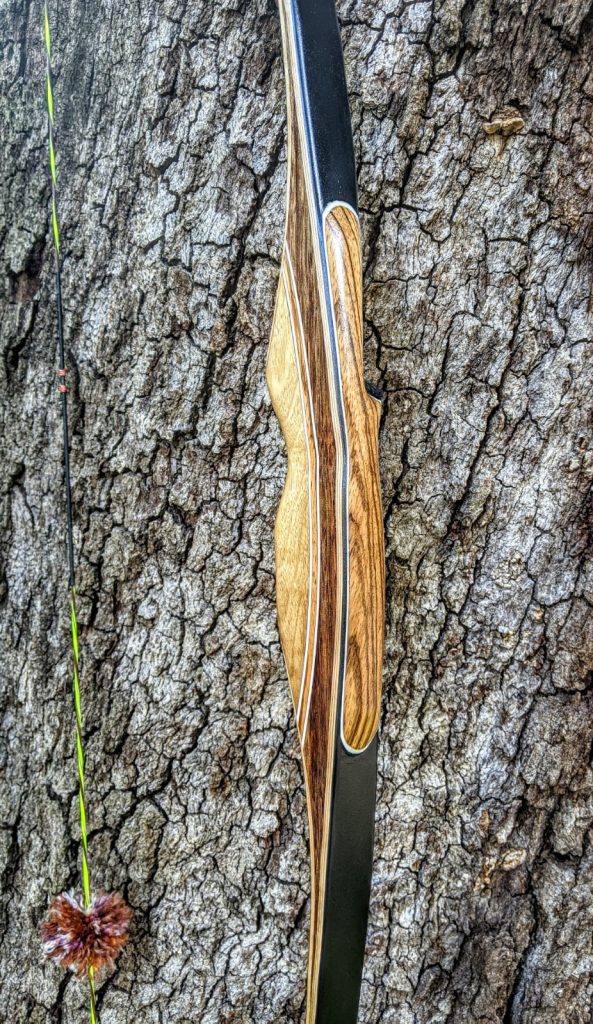

This reflex/deflex one-piece longbow is smoothly tapered and feels light in the hand. The riser woods are brownheart and myrtle accented with marblewood and white G10 glass, laminated with G-Flex 650 epoxy and cured for 3 hours at 140 degrees. The limb construction is a back layer of black fiberglass backed with .020” carbon fiber, 3 parallel strips of hard maple, a tapered layer of hard maple and a black fiberglass belly. The bow was glued-up with Huntsman TDR-1100 high strength epoxy, oven cured at 165 degrees for 6 hours and shaped by hand, resulting in a tough but smooth shooting bow. The riser overlay of zebrawood and white G10 and resin-stabilized marblewood limb tips enhance and add strength to the bow, which is designed for high-performance bowstrings (a 14 strand 8125G continuous loop string is included). The tough satin finish consists of 3 coats of Thunderbird Epoxy hand rubbed with 0000 steel wool and bowling alley wax.

| AMO Length | 64″ |

| Draw Weight | 39# @ 28″ |

| Brace Height | 7 1/2″ |

| Tiller | Even |

| Nock Height | 1/2″ |

Test Arrows:

Black Eagle Instinct, 31 1⁄2”, 600 spine, 125 gr. Points

Easton X7 Eclipse, 27”, 1914 (0.658), 100 grain NIBB Points

@ 20 Yards

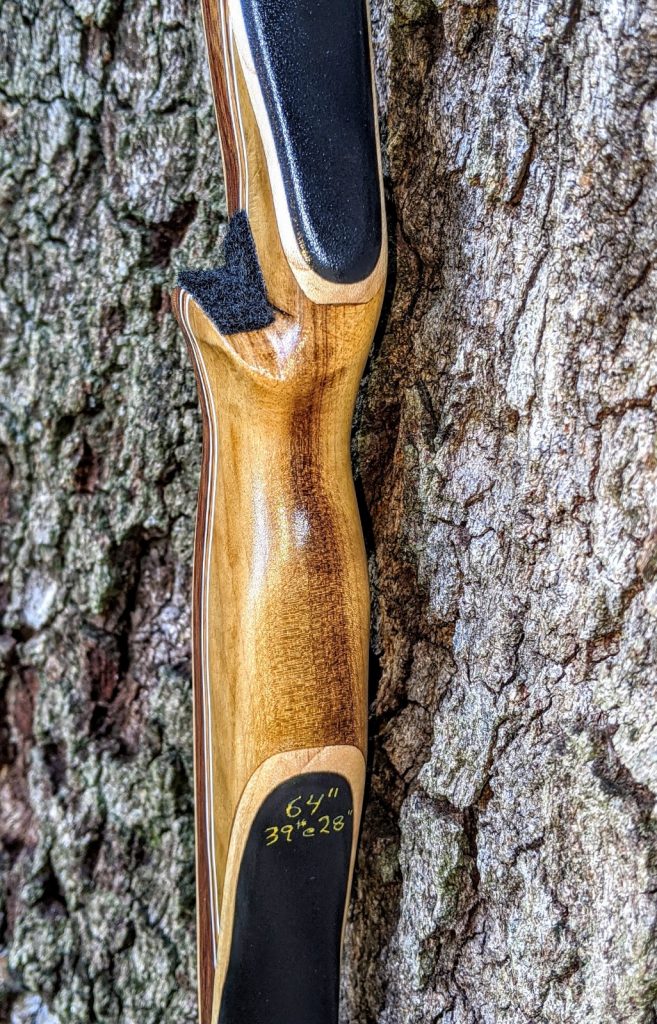

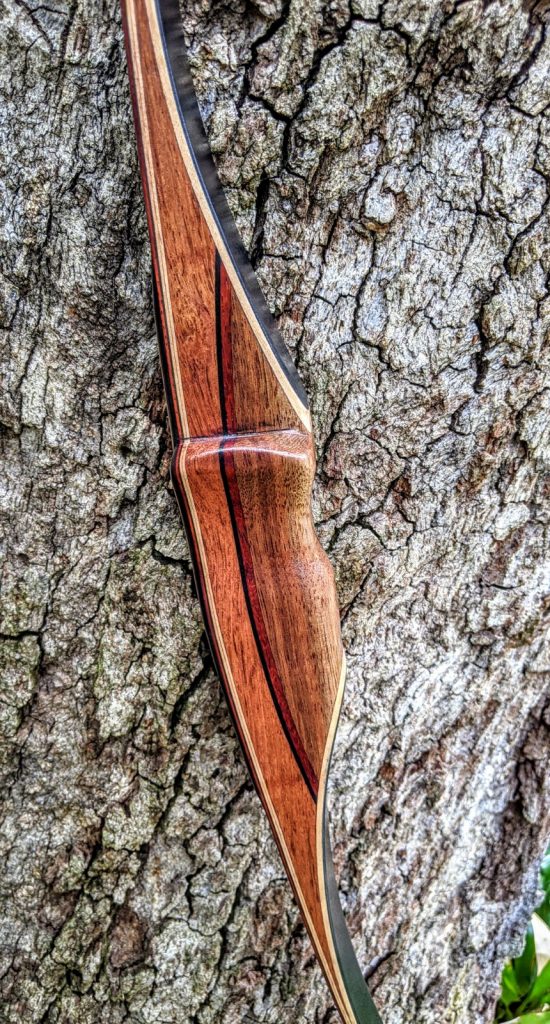

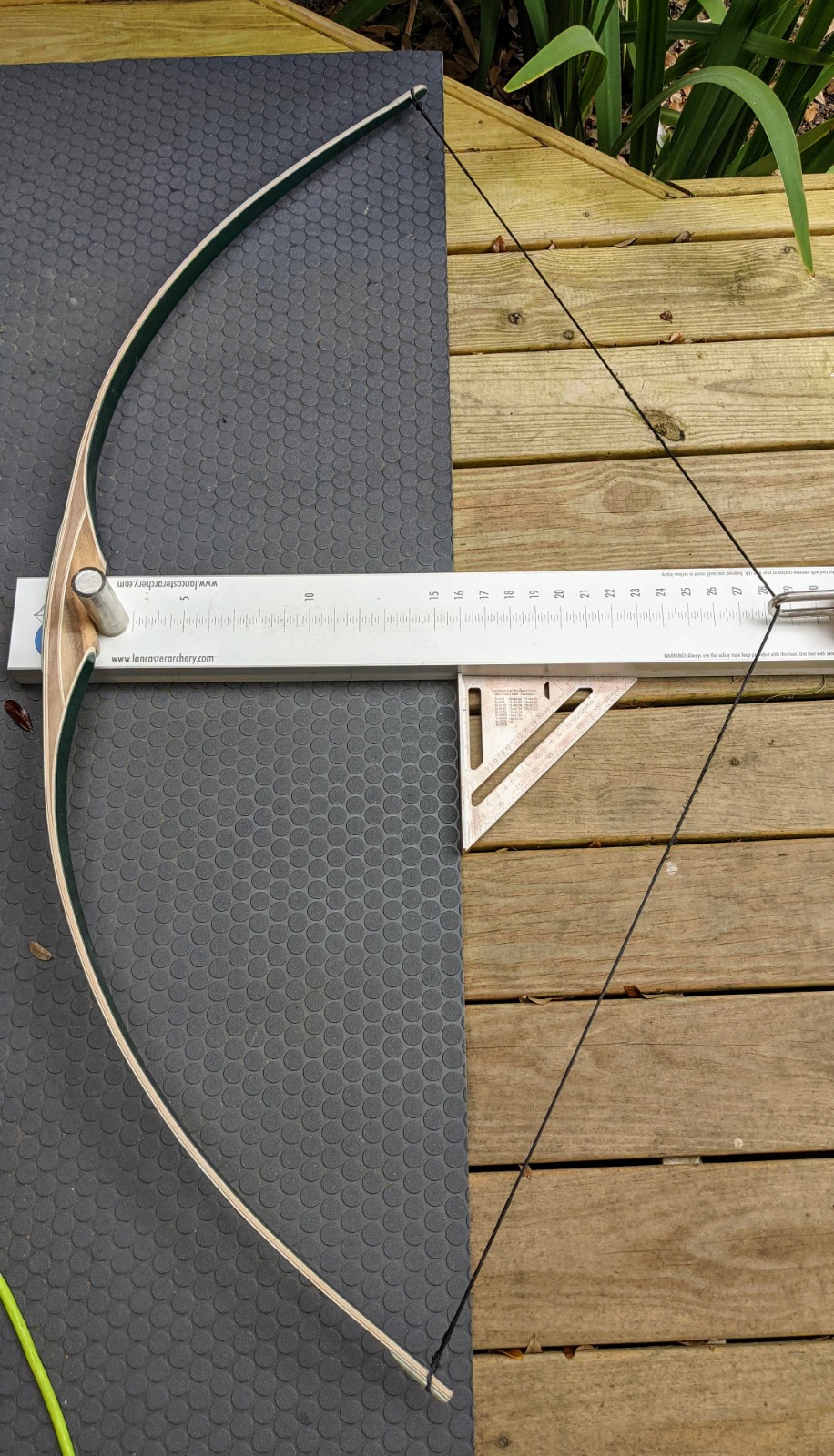

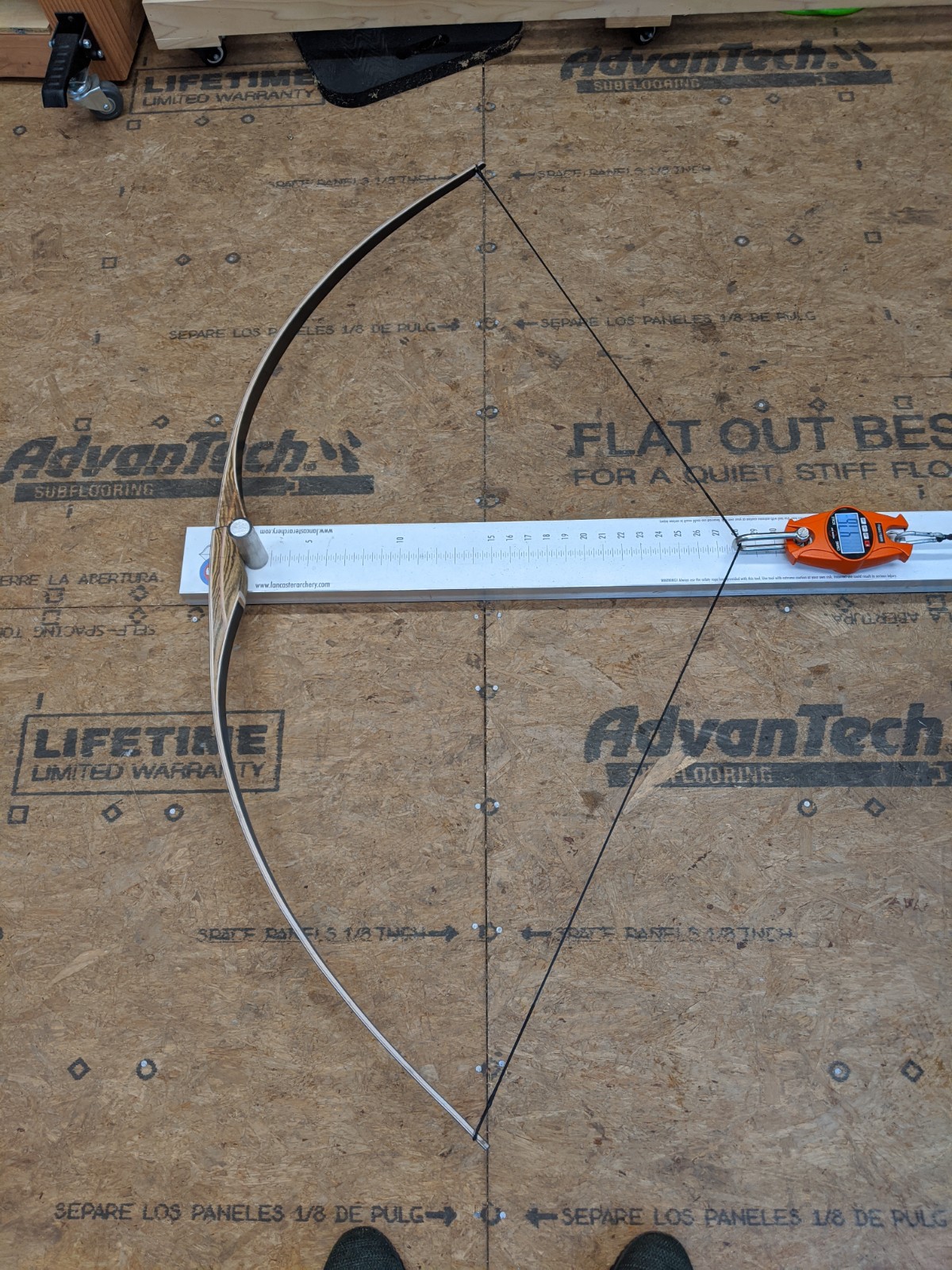

Sean’s classic one-piece longbow is designed with tapered reflex/deflex limbs for a smooth feel and high responsiveness.

The riser is constructed of domestic hardwoods Walnut and Myrtle, with an accent strip comprised of white, high strength G-10 epoxy/fiberglass and Zebrawood (West Africa). The riser components are laminated with Huntsman TDR 1100-11 industrial epoxy cured for 3 hours at 180 degrees.

The limbs consist of 1 tapered and 3 parallel strips of hard maple sandwiched between back and belly layers of green fiberglass. A .030″ layer of carbon fiber is laminated in the core for increased strength, stiffness and performance. These layers and the riser block were glued-up with Smooth-On EA-40 high strength laminating resin, oven cured at 160 degrees for 6 hours and shaped by hand.

A white G-10 and Zebrawood overlay was applied to enhance the grip and the limb tips were reinforced with green dyed and resin stabilized Zebrawood and G-10 to handle high-performance bowstrings (included is a BCY 8125G continuous loop string silenced with merino wool yarn, hand-spun and dyed by Gale’s Art).

Finally, the bow was spray finished with 12 coats of Thunderbird Epoxy and hand rubbed with 0000 steel wool and bowling alley wax, resulting in a rugged bow that will welcome daily use in any element. Enjoy this great shooter!

| AMO Length | 64″ |

| Draw Weight | 48# @ 28″ |

| Brace Height | 7 1/2″ |

| Tiller | Even @ 28″ |

| Nock Height | 5/8″ |

Test Arrows:

PSE Carbon Force Timber

| Spine | 500 |

| Length | 30″ |

| Point Weight | 150gr |

| Total Weight | 389gr |

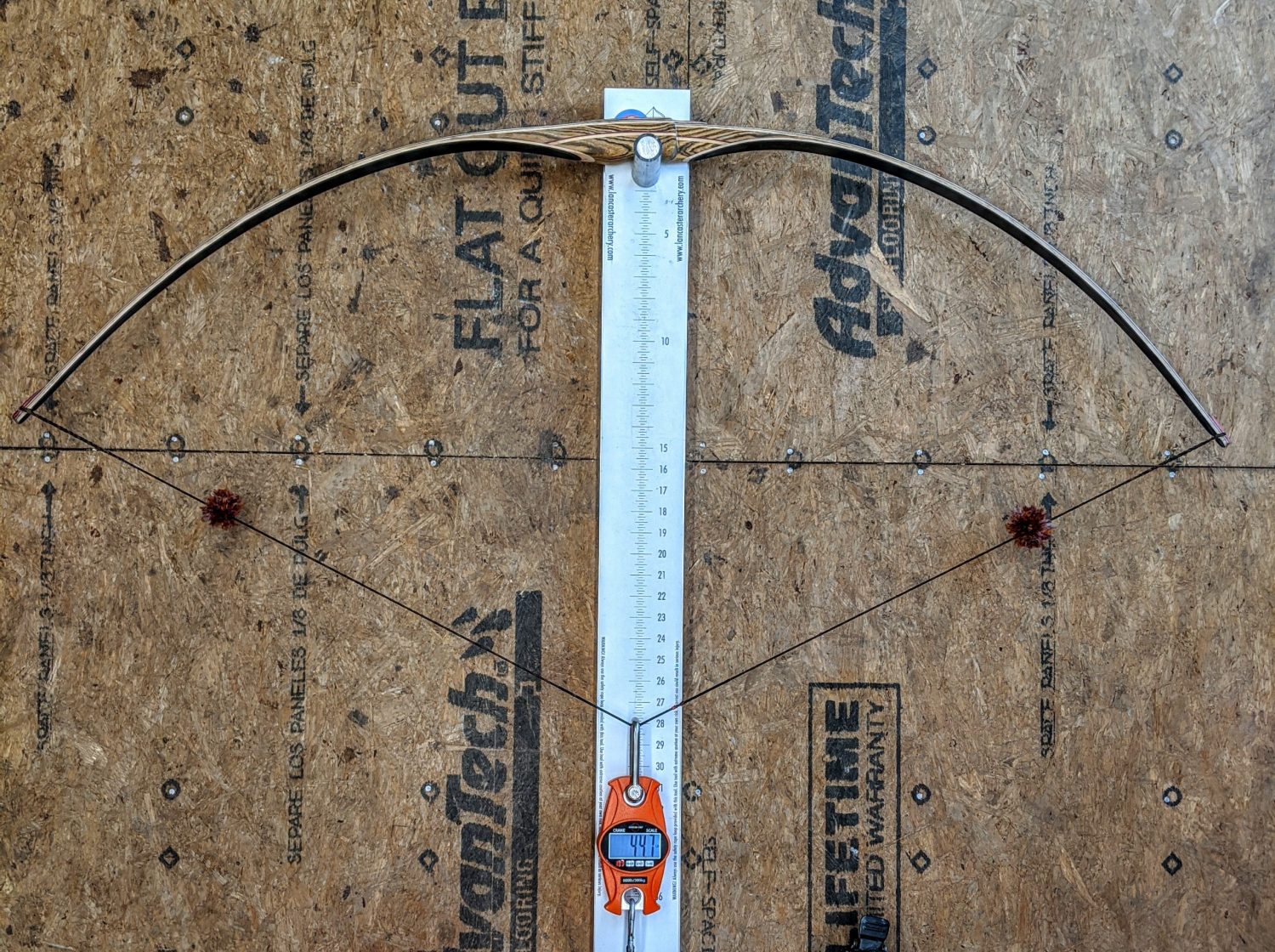

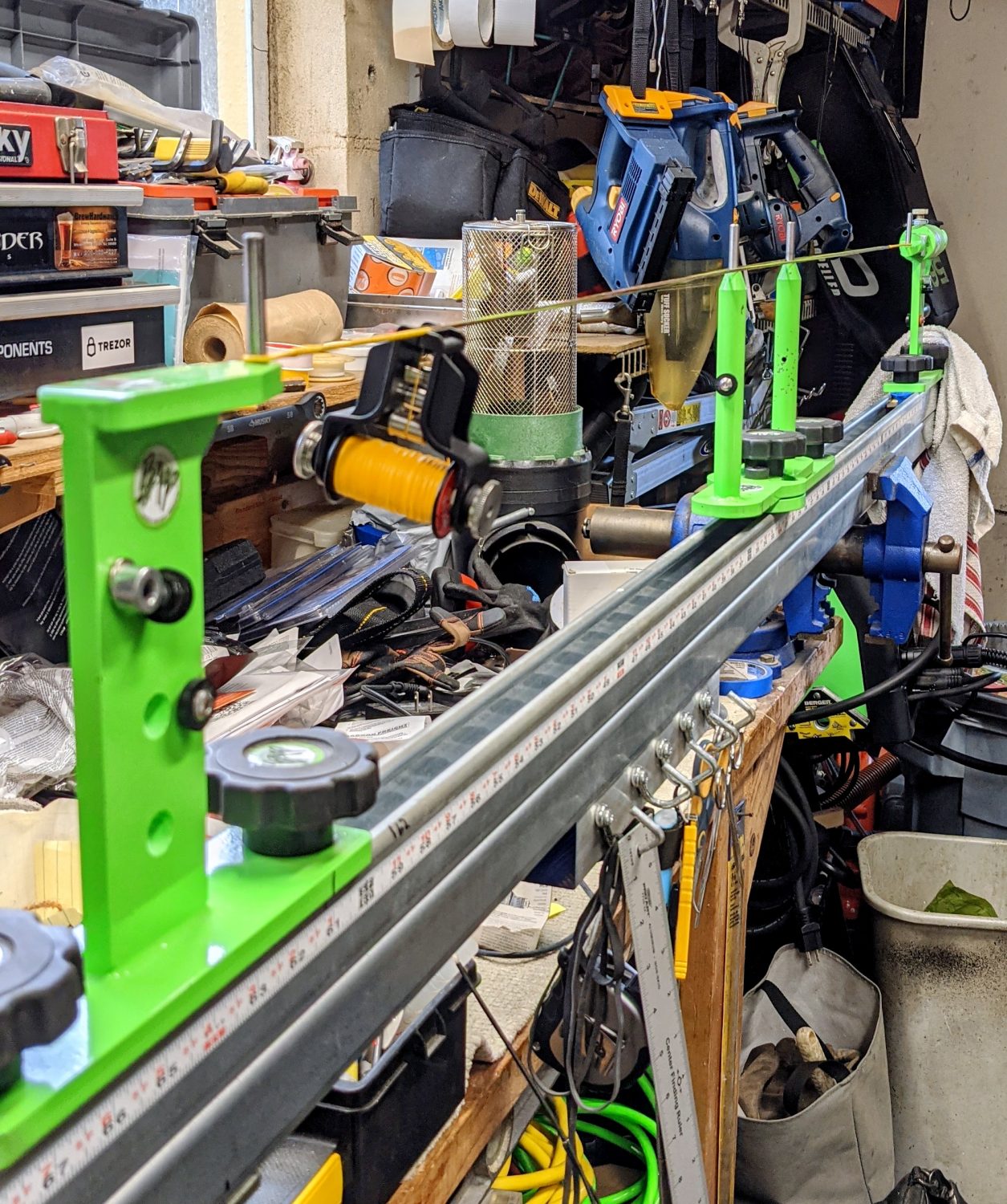

Build Process

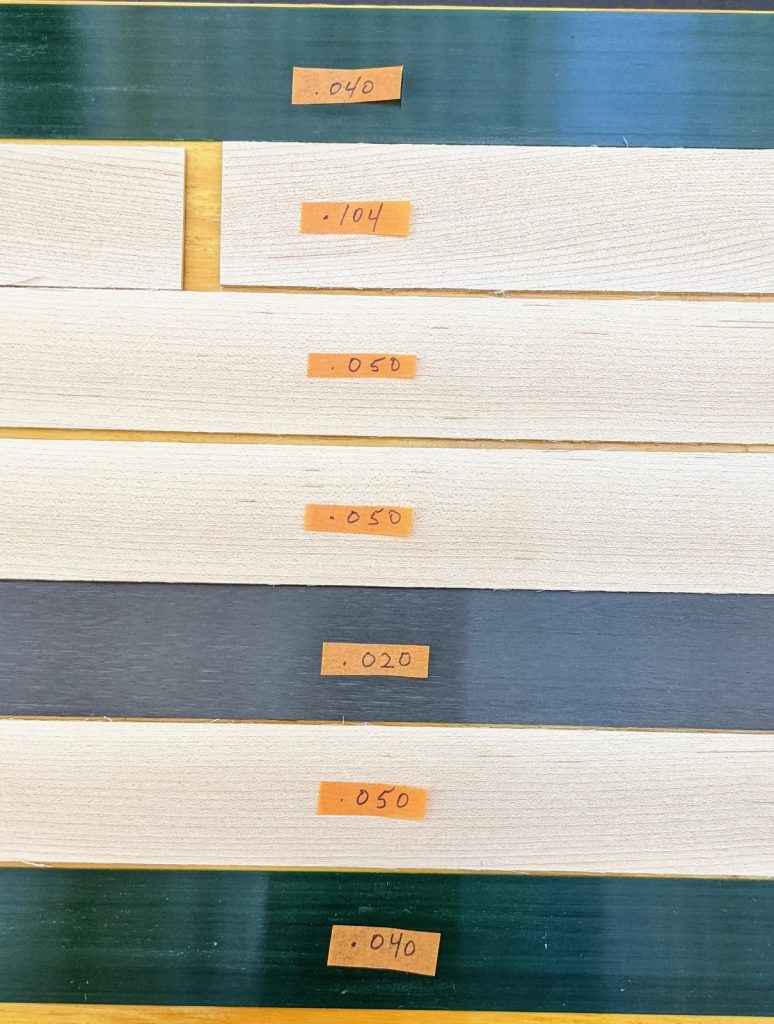

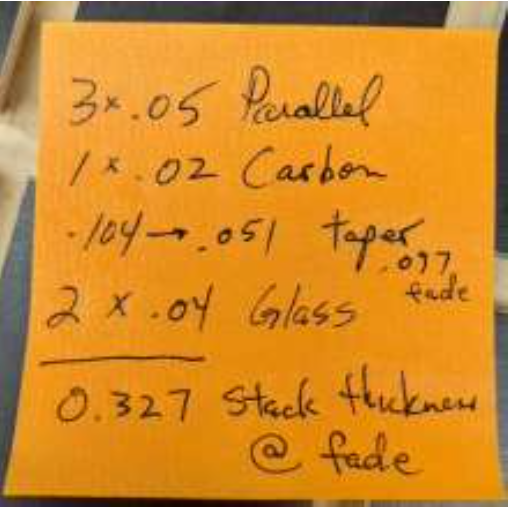

1. Select riser wood and limb materials .(Spec for 50# +/- 5#)

2. Cut, glue and shape riser.

3. Clean and sand laminations. Apply epoxy to lams and riser and place in form. Inflate pressure hose to 60# to ensure tight bonds with no gaps.

4. Place form in oven and bake for 6 hours at 160 degrees.

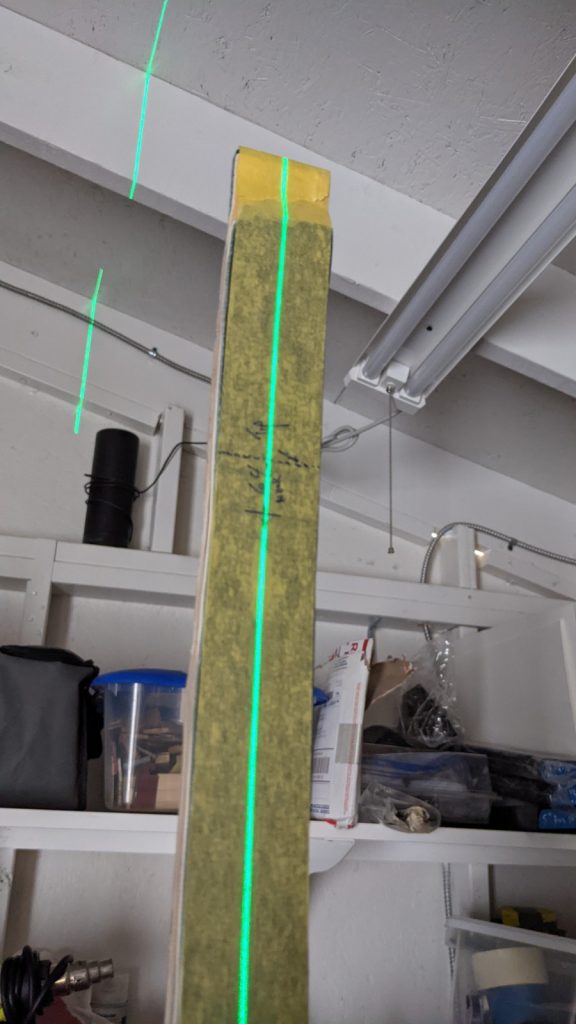

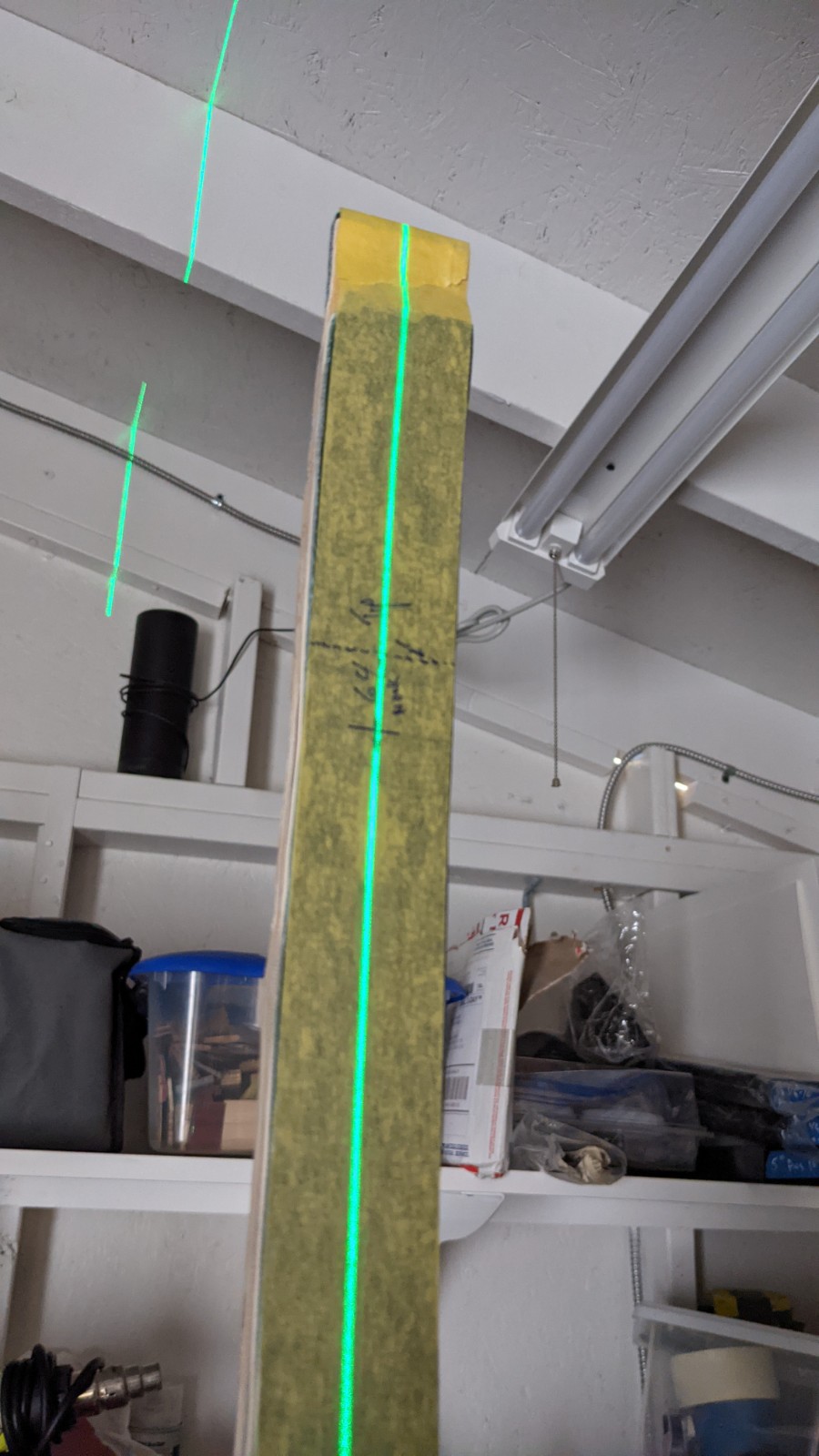

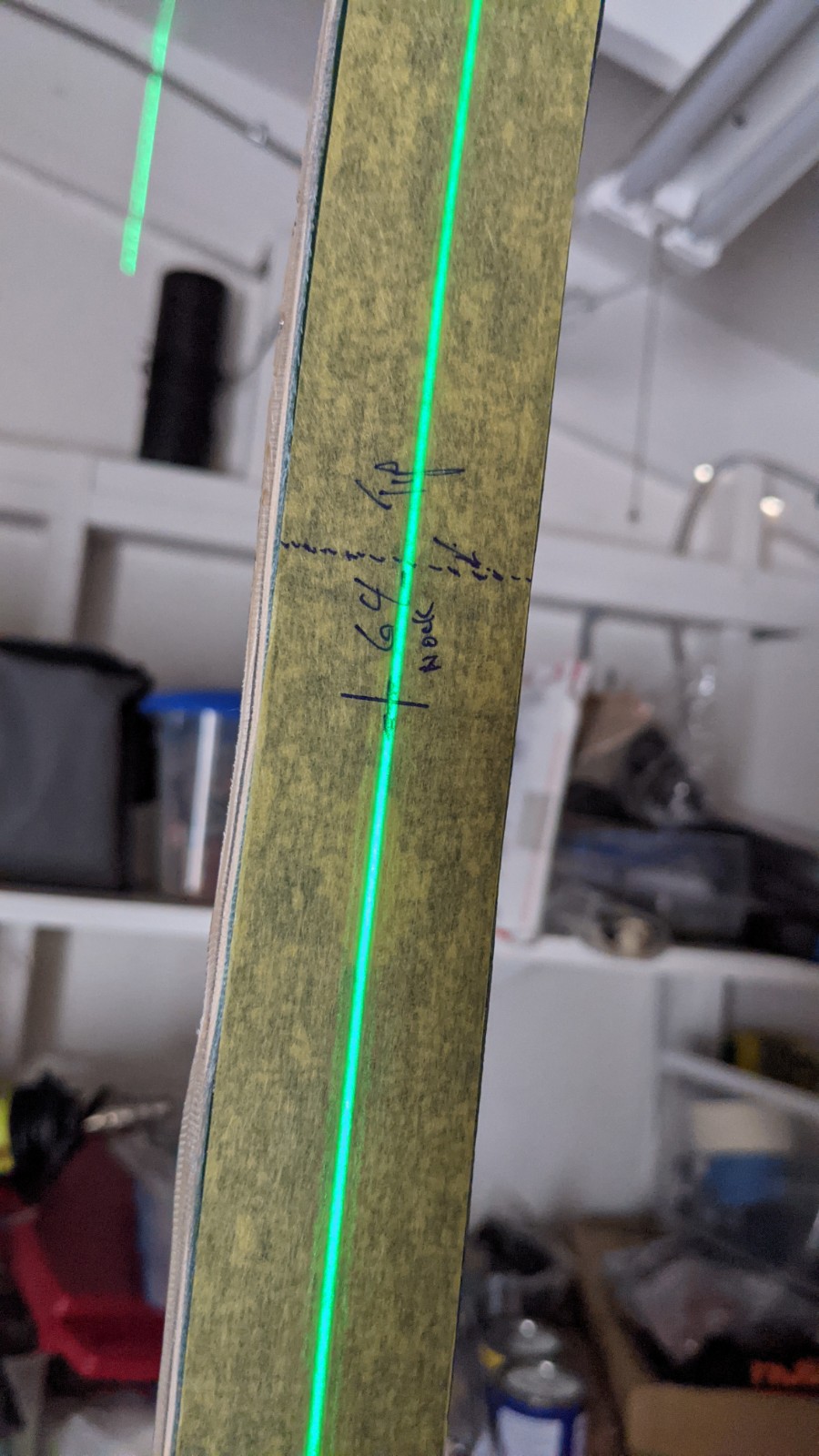

5. Prepare to shape and lay out exact centerline with laser.

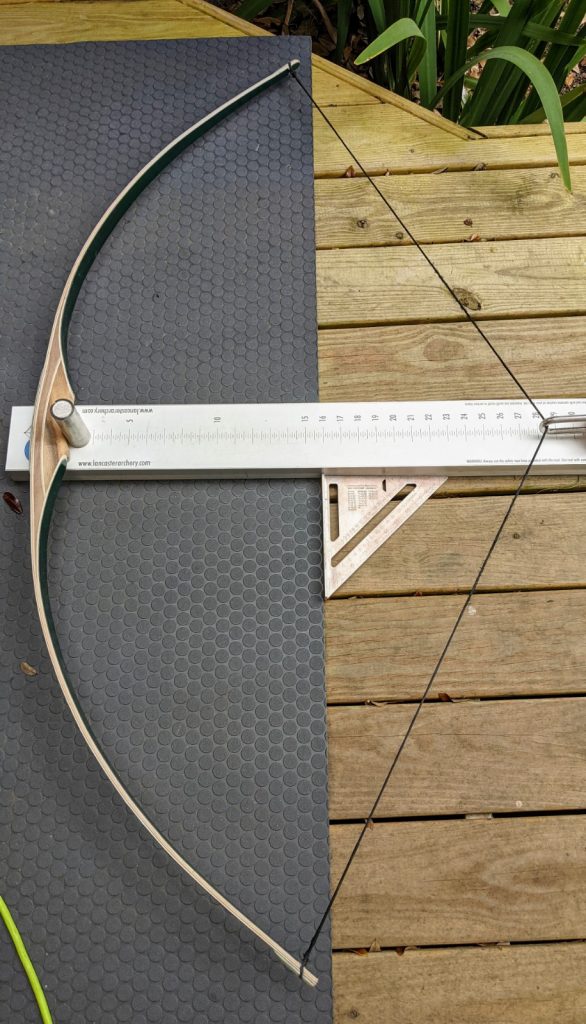

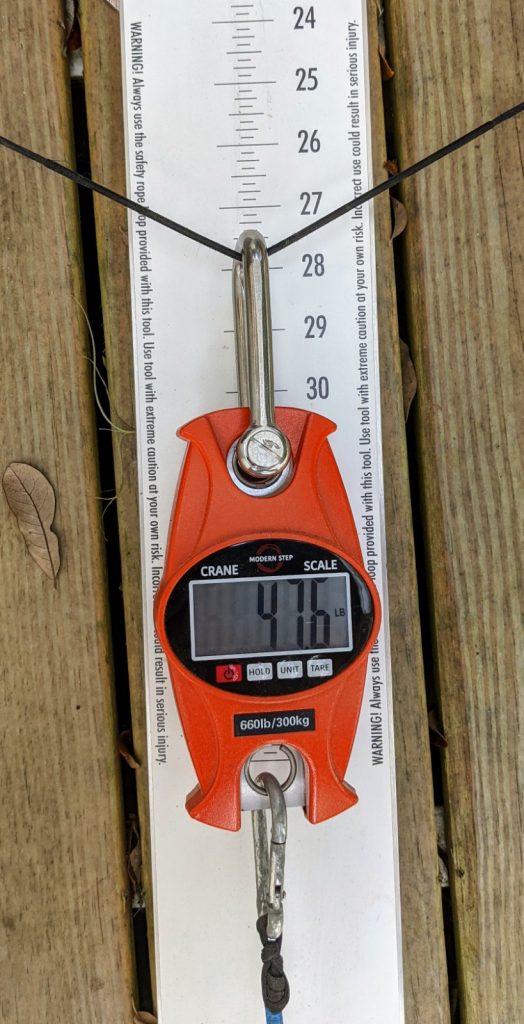

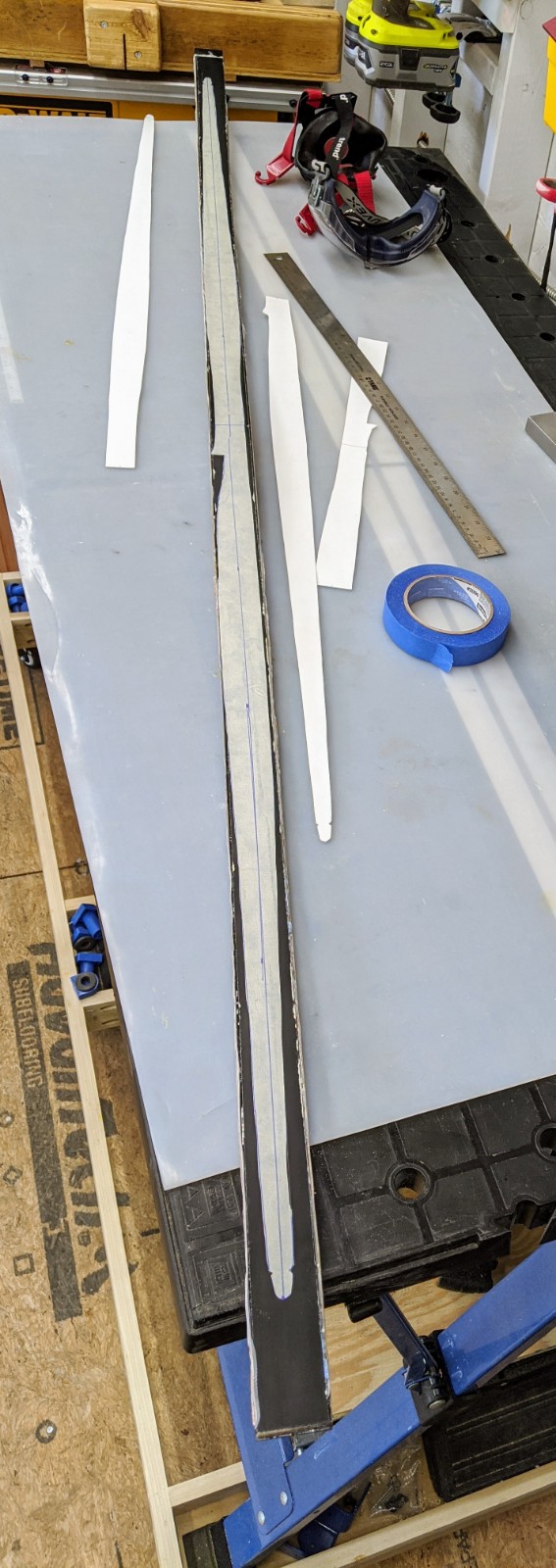

6. Cut out profile with bandsaw and rough shape with files and edge/spindle sander. Check for limb twist and adjust tiller and draw weight.

7. Continue final shaping and sanding. Apply overlays and file string grooves.

8. Prepared for finishing.

9. Spraying Thunderbird Epoxy. (. . . and making a string between coats)

This classic one-piece longbow is designed with tapered reflex/deflex limbs for a smooth feel and high responsiveness. The riser is constructed of three hardwoods (myrtle, marblewood and brownheart) with an accent strip of

high strength G-10 fiberglass. The riser components are laminated with G- Flex 650 epoxy cured for 3 hours at 140 degrees. The limbs consist of 1 tapered and 3 parallel strips of hard maple sandwiched between back and belly layers of black fiberglass. A .030″ layer of carbon fiber is laminated in the core for increased strength, stiffness and performance. These layers and the riser block were glued-up with EA-40 epoxy, oven cured at 165 degrees for 6 hours and shaped by hand, resulting in a tough but smooth shooting bow. The limb tips have been reinforced with layered brown and black G-10 to handle high-performance bowstrings (included is a BCY 8125G continuous loop string silenced with merino wool yarn, hand-spun and dyed by Gale’s Art). Finally, the bow is finished with 4 coats of shellac top coated with 3 coats of Thunderbird Epoxy and hand rubbed with 0000 steel wool and bowling alley wax. This is a rugged bow that will welcome daily use in any element. Enjoy this great shooter!

| AMO Length | 64″ |

| Draw Weight | 48# @ 28″ |

| Brace Height | 7 1/2″ |

| Tiller | + 1/4 @ 28″ |

| Nock Height | 5/8″ |

Tested Arrow:

PSE Carbon Force Timber 500 Spine 30” 150gr point total weight 389gr

This classic reflex/deflex one-piece longbow is smoothly tapered and feels light in the hand. The riser woods are bubinga and jatoba accented with padauk and black G10 glass, laminated with G-Flex 650 epoxy and cured for 3 hours at 140 degrees. The limb construction is a back layer of clear fiberglass over a strip of red padauk, 2 parallel strips of hard maple, a tapered layer of hard maple and a belly layer of black fiberglass. A .020″ layer of carbon fiber is laminated behind the padauk for increased strength and performance. The bow was glued-up with Huntsman TDR-1100 high strength epoxy, oven cured at 165 degrees for 6 hours and shaped by hand, resulting in a tough but smooth shooting bow. Resin-stabilized marblewood and G10 glass riser and limb tip overlays enhance and add strength to the bow, which is designed for high-performance bowstrings (a 16 strand 8125G continuous loop string is included). For the utmost in durability, the bow was sprayed with a textured finish of 3 coats of Thunderbird Epoxy hand rubbed with 0000 steel wool and bowling alley wax.

| AMO Length | 62″ |

| Draw Weight | 40# @ 28″ |

| Brace Height | 7 3/4″ |

| TIller | Even |

| Nock Height | 3/4″ |

Test Arrows:

Black Eagle Instinct, 31 1⁄2”, 600 spine, 125 gr. points